Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

|  موضوع: Specification of Water Wells/Lمواصفات مياه الابار والمعايير الاساسية لانشاء ابار صالحة للشرب موضوع: Specification of Water Wells/Lمواصفات مياه الابار والمعايير الاساسية لانشاء ابار صالحة للشرب  السبت مارس 03, 2012 4:18 pm السبت مارس 03, 2012 4:18 pm | |

| Specification of Water Wells

BY

GENERAL.DR

BAHAA BADR

TECHNOLAB EL-BAHAA GROUP

ABSTRACT

The water well, or wells serving a groundwater heat pump

(GWHP) system, are as pivotal a part of the mechanical design

as the boiler and cooling tower would be in a water loop

system.

As such, they should warrant the same degree of attention

with respect to specification as the more conventional

components would receive.

Unfortunately, this is rarely the

case, and the HVAC design engineers’ lack of familiarity with

the topic is sometimes at fault. This paper is intended to identify

the key sections of water well specifications and briefly discuss

their contents.

INTRODUCTION

The design and construction of water wells is a topic unfamiliar

to many, if not most, mechanical engineers.

As a result,

the task is often poorly handled, or worse, ignored. This rarely

results in a well completed in the best interests of the owner.

Although the HVAC engineer may not always be directly

responsible for the design of the well, its specification, or

construction management, they are, in the context of a groundsource

heat pump system, a critical part of the mechanical

design.

Consequently, it is in the interest of the HVAC design

engineer to become familiar with the terminology of water

wells and the key specification issues relating to their

construction.

The goal of this paper is not to provide suggested

specification text but to briefly discuss the key sections found

in a well-specification document and comment on the contents

of each.

WATER WELL TYPES

The design of a water well and the preparation of the

construction documents related to it are functions of several

documents related to it are functions of several

issues, including the purpose of the well (domestic, municipal,

irrigation, injection, etc.),

its capacity (low <10 gpm [0.6 lps]),

medium 10 - 100 gpm [0.6 - 6.0 lps], high >100 gpm [>6.0

lps]),

the geology penetration (consolidated, unconsolidated,

combination), and the construction method (mud rotary, air

rotary, reverse circulation, cable tool) (EPA 1975).

Since this

paper is limited to wells serving commercial GWHP systems

(normally medium to high capacity, rotary constructed), the

primary influence on design and specification is the nature of

the geology penetrated in the process of construction.

Although there are an infinite number of well construction

designs, for a substantial part of the country the alternatives

can be reduced to some variation on one of the two basic

designs .

Special modifications to

these basic designs can be made to accommodate conditions

such as artesian aquifers, injection rather than production, and

corrosive water.

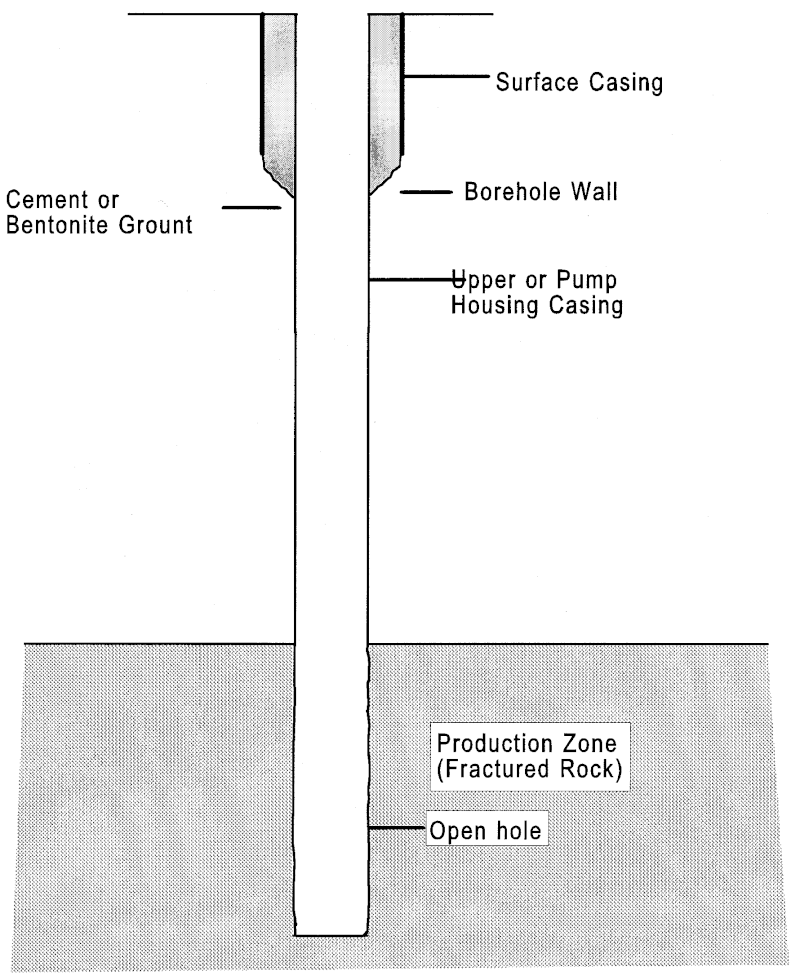

The simplest well is one completed in rock

formations in which the water is produced from fractures in

the rock.

In these wells, sometimes called “open hole completions,”

no casing or screen is necessary to stabilize and filter

the aquifer materials adjacent to the well bore due to the nature

of the geology.

Casing is normally placed in the upper portion

of the well for a short distance to accommodate the installation

of a surface seal.

The second type of well, completed in unconsolidated

materials (sand, gravel, clay, soil, and mixtures thereof), is

more complex.

In these applications the well is completely

lined with casing, screen, and sometimes an artificial filter or

“gravel pack.”

In unconsolidated settings, the variation in the

size of the aquifer materials results in the need to adequately

filter the water entering the well to control the content of sand

in the water produced.

In some cases, a screen alone, attached

to the bottom of the casing, will provide the necessary filtering

of the water.

In other cases, the screen must be accompanied

by an artificial filter or gravel pack located between the screen

and the borehole wall.

This gravel is sometimes only a formation

stabilizer of relatively uncomplicated description.

For

other situations, a more carefully specified filter gravel must

be used.

The need for accurate descriptions of these components

and their installation results in a more voluminous specification

document for these wells than for an open hole well.

WATER WELL TERMINOLOGY

Prior to discussing the details of individual well specification

sections, it is useful to review a few of the key terms

relating to water wells and their operation.

includes

many of these terms. In any well, under nonpumping conditions,

the level at which the water resides in the well is known

as the static water level.

When the pump is started, the water

level will drop to a new level known as the pumping level, and

this level is a function of the pumping rate.

The difference

between the static water level and the pumping level is

referred to as the drawdown.

Dividing the pumping rate by the

drawdown yields a value known as the specific capacity with

units of gpm/ft (lps/m).

This value provides a rough indication

of the aquifer/well capacity to produce water.

The drawdown

is the manifestation of the “cone of depression,” which forms

around the well in response to pumping.

The lower portion of the well in the production zone may

be completed with only a borehole (in rock formations), a

screen, or a screen and an artificial filter (gravel pack),

depending on the nature of the aquifer materials.

Casing is

placed in the well to support the borehole and prevent collapse

to accommodate the installation of a pump or to facilitate the

placement of a seal.

The diameter of the innermost well

casing, known as the pump housing casing, is primarily a function

of the size of the pump to be installed.

Submersible

pumps, the type most often used in GWHP systems, often

require one size smaller casing due to their operation at 3600

rpm than line shaft driven pumps, which normally operate at

1800 rpm or less.

Other well casing is sometimes installed in

the upper portion of the well to accommodate the installation

of the surface seal. The surface seal, often a cement grout,

prevents surface water from draining down between the casing

and borehole into the subsurface.

WELL SPECIFICATION ISSUES

There are several areas that should be addressed in the

course of preparing a specification for a water well, and Table

1 presents the most important of these.

Some issues relate only

to certain types of wells or conditions, but this table is a useful

checklist for the specification process.

There are two

approaches to the design and specification of a water well. If

there are other wells nearby producing from the same formation

and approximately the same yield, the design of a new

well can be based upon the existing wells.

This is an acceptable

practice assuming the existing wells operate without

problems.

In other cases, the well design is determined to a

large extent by the geology and aquifers it penetrates.

A

preliminary design can be developed, but it may be necessary

to modify this in the course of construction.

For a well completed in a consolidated formation (rock),

the sections on screen, gravel, and sometimes development

can be eliminated.

Scope of Work

This is the section in which a general description of the

work is provided.

The scope at a minimum includes the type

of drilling rig to be used, approximate depth, number of wells,

and the expected yield for production wells.

When available,

the scope may also provide additional detail on the general

construction of the well in terms of casing size, depth, screentype

diameter, location, and development method.

If a performance

guarantee with respect to yield, or specific capacity is

required, this is also included in the scope section (RMC

1985).

Nontechnical Well Issues

Nontechnical well issues (a phrase used in this paper and

not in the specification document) include items not directly

related to the technical details of construction.

Contractor

qualifications, site description, noise control, archeological

discovery, and facilities provided by the owner are normally

covered as individual sections but are grouped together here

for simplicity.

The paragraph on contractor qualifications normally

includes a minimum experience requirement (number of wells

similar to the current project, years in business) and a licensing

requirement.

Details for a list of reference projects may also be

spelled out.

The site description is especially important,

particularly if potential drillers are from outside the area.

A

physical description of the site is provided along with background

on the geology/hydrogeology. If available, well

completion reports from nearby wells are a key part of this

information.

Noise is normally addressed through the specification

of acceptable operating hours for drilling operations.

The facility provided by the owner is one of the few specification

issues actually requested by contractors, particularly in

the case of site access and water availability.

Sufficient water

supply for the drilling operation is a critical issue.

Equipment Requirements

In this section, a specification is made with respect to the

drilling rig capabilities required and/or a form is provided on

which the contractor must submit a description of the equipment

to be used in the construction of the well.

In cases of shallow

wells, such issues as mast, hook, and draw-work load

limits are not often approached, even for small rigs. As a

result, it is possible to omit this section in some small projects.

Drilling Fluid

This is a section that relates primarily to conventional

(direct) rotary drilling operations. In this section an accept-

able value, or range of values, for key drilling fluid (sometimes

called “mud”) parameters is provided.

The drilling

fluid, or mud, is circulated down the rotating drill pipe, out

the bit, and back up the annular space between the borehole

wall and the drill pipe.

It serves to lubricate and cool the bit,

carry away the cuttings, and form a “cake,” stabilizing the

borehole walls. Included are such characteristics as weight

(11 lb/gal maximum), marsh funnel viscosity (32-38 seconds

maximum), 30-minute water loss (15 cc maximum), filter

cake formation (2/32 in. [1.6 mm] maximum), and sand

content (2% maximum).

It should be understood that fluid

parameters are regularly adjusted in the course of drilling to

accommodate situations encountered in the construction

process. In some fluid specifications, reference is made to a

requirement for a drilling mud engineer’s involvement in the

project.

On small projects, these services are usually available

to the drilling contractor from the mud vendor, and the

specification of a mud engineer’s availability to the contractor,

rather than his on-site presence, is appropriate.

Drilling Program Submittal

This section provides the requirements for submission by

the contractor of a schedule of tasks to be completed in the

process of completing the well.

Included are personnel, schedule

of tasks (drilling, casing, screen gravel installation, development),

and details of the drilling fluid makeup (additives)

(RMC 1985).

Formation Sampling

Formation sampling is described as a pivotal part of the

well drilling process in this section.

Decisions are made, based

on samples from the production zone of the well, as to the

screen-slot size and gravel-pack gradation necessary for

completion.

If a pilot bore is used in rotary drilled wells, the

samples are taken as the pilot hole progresses.

If the approximate

depth of the production zone is known, it is normal practice

to specify a regular interval over which samples will be

taken; the handling, appropriate containers, and labeling of the

samples; along with the individual (or organization) to whom

they should be delivered.

Sieve analysis of these samples

provides the data upon which screen-slot size and gravel-pack

size distribution are based.

This consists of passing the

samples through a set of progressively finer sieves or screens

to determine the size distribution of the sampled material.

Logs/Records

Depending on the depth, drilling method, and purpose of

the well, a variety of logs and reports may be specified in this

section.

For wells of the type used for GSHP systems, it is

normally sufficient to specify the depth and physical description

of strata penetrated, the depth of water producing intervals,

associated static water levels, and penetration rates

accomplished on the driller report.

If well completion reports

the driller report.

If well completion reports

are required by regulatory agencies, copies should be provided

to the owner/engineer as well.

Reporting requirements for

flow testing, development, and plumbness/alignment are

covered in those respective sections.

Plumbness/Alignment

Plumbness (deviation from the vertical) and alignment

(“straightness”) of the well are issues of importance with

respect to the installation of a pump in the well. In particular,

lineshaft-type pumps are much more sensitive to the alignment

issue than are submersible pumps.

With a rotating shaft

extending from the surface to the pump (sometimes hundreds

of feet down in the well), wells in which line-shaft pumps are

to be installed must be held to tighter tolerances than submersible

installations.

Two approaches can be taken to this specification.

For small projects using a submersible pump, the

required test often involves a 40 ft (12 m) section of pipe, 2

in. (12 mm) smaller in diameter than the inside of the casing,

which must be capable of passing freely through to the bottom

of the pump housing casing.

For larger wells, or those using

line shaft pumps, a more sophisticated test involving a device

for measuring deviation of the bore is necessary.

Casing

Casing is a term that refers to tubular material extending

from the surface to some depth in the well.

It is installed to

accommodate the sealing of the well, to stabilize the walls of

the borehole, or to allow the installation of screen or liner

(tubular products not extending to the surface).

In shallow

wells of the type serving GWHP systems, at least two types of

casing are often found. Surface casing is installed a short

distance (to the first impermeable strata or minimum of 18 ft

[6 m] by many codes) from the surface to a depth sufficient to

allow the installation of the surface seal (usually cement grout)

between the surface casing and the well bore.

The surface

casing also helps to support near-surface unconsolidated

materials during the drilling operation.

Sometimes this surface

casing is removed as the grout is placed.

The second casing type is the pump-housing casing,

which, as the name implies, is the casing in which the pump is

installed.

This casing is installed inside the surface casing,

from the surface to the top of the screen in gravel pack wells

or to the top of the producing interval in shallow open hole

wells.

If used, the screen would be attached to the bottom of

the pump housing casing.

In the casing portion of the specification information, the

size, wall thickness, material, and installation method of the

casing are provided, along with the location (depth) in some

cases.

Surface casing is normally at least 2 inches larger than

the pump housing casing in order to accommodate the placement

of the grout to an adequate thickness.

Diameter of the

pump housing casing is a function of the pump to be paced in

the well. Generally, it is desirable to have a pump housing

casing of two nominal sizes larger than the pump to be

installed.

Pump bowl (impeller housing) diameter is related to

pump type and flow rate. Submersible pumps, which typically

operate at 3600 rpm, produce more flow per unit diameter than

line shaft pumps, which operate at 1800 rpm or less. In most

commercial applications, a minimum of 6 in. (150 mm) casing

would be used with 8 in. (200 mm) for flows >100 gpm (6 lps)

and 10 in. (250 mm) for flows > 300 gpm (18 lps) (Kavanaugh

and Rafferty 1997).

Casing wall thickness is normally specified

in this section. Wall thickness requirements vary with

drilling method, depth, diameter, and seal placement. In

general, for sizes up to 14 in. (350 mm) and depths to 600 ft

(180 m), a 250 in. (6 mm) wall thickness is acceptable

(AWWA 1997).

Most wells serving commercial applications

use carbon steel well casing.

Plastic materials can be used in

a very shallow applications permit. Detailed specifications are

available on the placement of the casing; however, drilling

method (rig type) largely determines the techniques used, and

in many cases, this issue simply adds needless detail to the

well specification.

Screen

The screen plays a critical role in the performance of the

well since it provides the filtering of the water entering the

well. In this section, the type of screen, aperture size, diameter,

length, entrance velocity, and material of the screen are

described, along with the installation method.

The determination

of aperture (slot) size is made based on the results of a

sieve analysis of the drill cutting samples from the production

interval of the well.

On occasion, when sufficient information

is available, the screen can be specified based on the performance

of existing wells in the same aquifer.

For this to be an

effective strategy, detailed knowledge of the geology must be

available. In applications where no gravel pack will be used,

the screen slot size is specified as that which will retain 30%

to 50% of the aquifer materials, depending on the corrosiveness

of the water and the uniformity coefficient of the aquifer

materials.

In applications where a gravel pack will be used, the

slot size is selected for retaining 70% to 100% of the gravel

pack materials (AWWA 1997).

All slot size selections are

based on the aquifer materials sieve analysis distribution

curve.

The specification can allow the contractor to have a lab

do the analysis with the results delivered to the owner/engineer

for approval, or the samples can be delivered directly to

the owner/engineer for analysis.

There are several types of screens available, and two of

the most common are wire-wound and louvered. Wire-wound

screens (continuous slot) provide a higher degree of open area

through which the water can pass (a critical issue in fine sand

aquifers), are generally more expensive than other types, and

with larger diameters are lower in collapse strength.

Louvered

screens are generally less expensive, have higher collapse

strength and lower open area, and provide for more effective

development using swabbing.

Entrance velocity specification

influences the type of screen.

In many references (some written

by a major manufacturer of wire wound screen) an

entrance velocity limit of 0.1 ft/sec (0.03 m/s) is cited. This

low velocity tends to require the use of screens with high open

area ratios (wire wound).

Other research suggests that

entrance velocities of as much as an order of magnitude

greater than this do not significantly reduce well performance

in many applications.

Wire-wound screens are normally

constructed of 304 stainless steel to reduce corrosion problems.

Louvered screens can be of carbon steel in many applications

due to their higher strength.

Placement of the screen, like the placement of the casing,

is best left to the contractor since it is determined to a large

extent by drilling method.

Gravel

Gravel is sometimes placed outside the screen to support

the aquifer materials (called formation stabilizer) or to

increase near bore permeability and to assist in filtering aquifer

materials (called artificial filter).

Regardless of function,

the common term for the practice is gravel pack.

The importance

of the selection of the size distribution of the gravel

material is much greater when it is intended to serve as an artificial

filter.

Issues to be addressed are size, gradation (uniformity

coefficient), geology, thickness, and placement.

As in the case of the screen slot size selection, the determination

of the gravel pack parameters is based on the cuttings

sieve analysis results.

One common criterion for the gravel

pack specifies that it have a 70% retained grain size of 4 to 6

times the 70% grain size of the cuttings sample and a uniformity

coefficient (40% size divided by 90% size) of not greater

than 2.5 (EPA 1975). Gravel material should be clean and well

rounded with a maximum of 10% flat surfaces and should be

a minimum of 95% siliceous in content (to avoid dissolution

in low pH water).

The thickness of the gravel pack should be between 3 in.

and 8 in. (75 mm and 200 mm) thickness. Placement of the

gravel is generally accomplished by either pouring from the

surface (in shallow wells) or by placement through a tremie (in

wells of greater than 1000 ft [300 m] depth) (RMC 1985). In

most shallow wells of the type serving GWHP systems, the

pack material will be poured from the surface.

This is done

while circulating drilling fluid down the drill pipe and up the

annular space (between the casing and the bore wall). A key

part of the specification is the requirement to maintain drill

fluid density below a specific density limit (9.1 lb/gal). The

fluid tends to pick up drilling mud from the walls of the borehole

as the gravel is placed. The viscosity limit requires this

material to be continuously removed during the process.

The

gravel placement should be completed in one continuous operation.

Development

The process of development is one in which the fines in

the aquifer material or gravel pack, and any remaining drilling

fluids in the near bore area, are removed by a variety of methods.

The development process is divided into two phases —

initial development using the drilling rig, and final development

by pumping after the rig has been removed.

To some

extent the type of development is influenced by the geology

and well type.

Specifications describe the type of development,

when it should be terminated, and, most importantly, the

acceptable sand production for the well in the final development.

In gravel pack wells, preliminary development is often

accomplished by the so-called “flushing” method, using a tool

known as a “double swab” that can be accomplished with the

rotary rig. A more effective method, known as line swabbing,

requires the use of a cable tool rig.

Both of these methods are

best applied with louver-type screens. Jetting is a development

technique often used most effectively with wire wound

screens, and it involves directing high-velocity water jets at

the screen/gravel pack.

Air-lift pumping and sand pumping

(used in naturally developed wells) are other methods of

development.

Preliminary development is carried on until all of the

fines and sediment have been removed from the gravel pack

and the pack ceases to settle.

Final development is carried on

until the specified sand content of the production water is

reached. This limit is typically expressed as a sand content in

ppm after some period of pumping.

Water samples for chemical

analysis can be taken toward the end of the preliminary

development or during final development pumping.

Water Samples

Water samples for the purpose of analysis for system

design (corrosion and scaling) should be taken during the

development pumping.

The specification describes the size of

the sample, the type of container in which it will be stored

(normally a container supplied by the lab doing the analysis),

and when the sample should be taken (after 1 hour of pump

operation).

Finally, the chemical constituents to be tested are

listed.

All major anions and cations, along with alkalinity,

total hardness, carbon dioxide, hydrogen sulphide, and

oxygen should be included.

Flow Testing

Flow testing of the well provides important data for the

design of the heat pump system since the groundwater flow

rate chosen is based on pumping power (flow and drawdown).

There are several types of flow tests that can be done on

a production well.

In many cases, a step drawdown test is done

for wells serving GWHP systems. In this test, the well is

pumped at three rates until water level has stabilized.

The

well. In many cases, a step drawdown test is done

for wells serving GWHP systems. In this test, the well is

pumped at three rates until water level has stabilized.

The

specification describes the flow rates, instrumentation (for

water level and flow data), frequency of readings, length of

test, and facilities for disposal of the water.

This so-called

single well test provides information primarily on the well

itself (yield, drawdown, specific capacity).

A more sophisticated

test in which nearby wells are monitored provides information

on the aquifer. These tests are rarely done for GWHP

systems.

Generally, the flows chosen approximate one-third, twothirds,

and full design flow anticipated for the system served.

Starting with the lowest flow, the pump is operated at a

constant rate until the water level in the well has stabilized, at

which time the flow is increased to the next rate.

Water level

is typically measured with an electric continuity device on the

end of a calibrated spool of wire.

Flow is measured with an

orifice plate discharging to atmosphere and pressure across the

plate monitored with a manometer.

Flow tests are often

subcontracted to a well pump contracting firm.

Some jurisdictions require that any well penetrating a

potential drinking water aquifer be sterilized.

The paragraph

relating to sterilization describes methods, chemical concentration,

and length of the sterilization procedure, which

normally consists of chlorine treatment.

Abandonment

In the event that the well is unsuccessful and cannot be

used for the intended purpose, it must be abandoned according

to the requirements of the regulatory agency responsible for

water wells.

Most states have very specific regulations covering

abandonment, which typically require filling the well with

an impermeable material—often cement grout.

It is not necessary

to cover these procedures in detail.

Referencing the

appropriate state administrative rule will suffice.

INJECTION WELL ISSUES

Injection wells, used for disposal of the water after passing

through the heat pump system, differ from production

wells in several ways.

Two of the more important are screen

design and seal placement.

Most references recommend a

water velocity through the screen of one-half of that used in the

production well.

It appears that this guideline is primarily

related to the allowance for plugging of the injection screen

with particulate carried into the well with the water.

From this

comes the widely held perception that the injection well

should have a larger diameter than the production well.

This

is not the case.

The reduced screen velocity can be achieved by

screening more of the aquifer since production wells in water

table aquifers normally screen only the lower one-half to onethird

of the aquifer.

Beyond this, the need for the additional

screen area assumes the presence of particulate in the injected

fluid. If the production well is sand free, or if a surface strainer

is used to minimize sand, the additional screen may not be

necessary.

Sealing of an injection well should be done in much the

same way as a production well penetrating an artesian aquifer.

The reason for this is that in the course of the operation of the

well, the pressure exerted on it is greater than the natural pressure

of the aquifer it penetrates.

As a result, there is a tendency

for water to migrate up around the casing toward the surface.

If the well is exposed to a positive pressure at the ground

surface, the potential exists for water to leak out around the

casing at the surface.

To prevent this, injection wells should be

sealed from just above the injection zone, continuously to the

surface, with a minimum 2 in. (50 mm) annular (between the

casing and the well bore wall) cement seal.

The injection stream should be introduced into the well

using an injection tube terminating below the water surface.

This prevents the injected water from cascading down from

the well head and generating air bubbles in the process.

Bubbles driven out into the aquifer can act as an obstruction to

water flow in much the same fashion as particulate matter.

SPECIFICATION TEXT

The goal of this paper has been to identify the key sections

necessary in a specification document for a water well and to

comment on the general contents.

Actual guide specification

text has been published by many others (RMC 1985; AWWA

1997; EPA 1975; MWWDA 1970).

In many cases these references

are published in the form of guidelines for the specification

of water wells in which explanatory paragraphs are

included ahead of actual specification sections.

Editing is

normally required to use these sources in construction documents.

| |

|

![[MSF+3.jpg]](https://2img.net/h/4.bp.blogspot.com/_SynCnHGx75g/Shl2T3oVhsI/AAAAAAAAAEY/_7oem5pvQ3I/s1600/MSF%2B3.jpg)