مجموعة تكنولاب البهاء جروب

تحاليل وتنقية ومعالجة المياه

|

تنظيف وتطهير وغسيل واعادة تاهيل الخزانات

معمل تكنولاب البهاء جروب

للتحاليل الكيميائية والطبية

والتشخيص بالنظائر المشعة

للمخدرات والهرمونات والسموم

وتحاليل المياه

مجموعة

تكنولاب البهاء جروب

لتصميم محطات الصرف الصناعى والصحى

لمعالجة مياه الصرف الصناعى والصحى

مجموعة تكنولاب البهاء جروب

المكتب الاستشارى العلمى

دراسات علمية كيميائية

معالجة الغلايات وانظمة البخار المكثف

معالجة ابراج التبريد المفتوحة

معالجة الشيللرات

مجموعة تكنولاب البهاء جروب

اسنشاريين

كيميائيين/طبيين/بكترولوجيين

عقيد دكتور

بهاء بدر الدين محمود

رئيس مجلس الادارة

استشاريون متخصصون فى مجال تحاليل وتنقية ومعالجة المياه

متخصصون فى تصنيع وتصميم كيماويات

معالجة الصرف الصناعى والصحى

حسب كل مشكلة كل على حدة تصنيع وتحضير كيماويات معالجة المياه الصناعية

مؤتمرات/اجتماعات/محاضرات/فريق عمل متميز     صور من وحدات معالجة المياه

technolab el-bahaa group technolab el-bahaa groupTECHNOLAB EL-BAHAA GROUP

EGYPT

FOR

WATER

TREATMENT/PURIFICATION/ANALYSIS

CONSULTANTS

CHEMIST/PHYSICS/MICROBIOLIGIST

INDUSTRIAL WATER

WASTE WATER

DRINKING WATER

TANKS CLEANING

CHAIRMAN

COLONEL.DR

BAHAA BADR EL-DIN

0117156569

0129834104

0163793775

0174041455 تصميم وانشاء محطات صرف صناعى/waste water treatment plant design technolab el-bahaa group egypt We are a consultants in water treatment with our chemicals as:- Boiler water treatment chemicals Condensated steam treatment chemicals Oxygen scavenger treatment chemicals Ph-adjustment treatment chemicals Antiscale treatment chemicals Anticorrosion treatment chemicals Open cooling tower treatment chemicals Chillers treatment chemicals Waste water treatment chemicals Drinking water purification chemicals Swimming pool treatment chemicals Fuel oil improver(mazote/solar/benzene) technolab el-bahaa group

egypt

We are consultants in extraction ,analysis and trading the raw materials of mines as:-

Rock phosphate

32%-30%-28%-25%

Kaolin

Quartez-silica

Talcum

Feldspae(potash-sodumic)

Silica sand

Silica fume

Iron oxid ore

Manganese oxid

Cement(42.5%-32.5%)

Ferro manganese

Ferro manganese high carbon technolab el-bahaa group

web sites

e-mails

water treatment unit design

وكلاء لشركات تركية وصينية لتوريد وتركيب وصيانة الغلايات وملحقاتها

solo agent for turkish and chinese companies for boiler production/manufacture/maintance

وكلاء لشركات تركية وصينية واوروبية لتصنيع وتركيب وصيانة ابراج التبريد المفتوحة

تصميم وتوريد وتركيب الشيللرات

design/production/maintance

chillers ابراج التبريد المفتوحة مجموعة تكنولاب البهاء جروب

المكتب الاستشارى العلمى

قطاع توريد خطوط انتاج المصانع

نحن طريقك لاختيار افضل خطوط الانتاج لمصنعكم

سابقة خبرتنا فى اختيار خطوط الانتاج لعملاؤنا

1)خطوط انتاج العصائر الطبيعية والمحفوظة والمربات

2)خطوط انتاج الزيوت الطبيعية والمحفوظة

3)خطوط انتاج اللبن الطبيعى والمحفوظ والمبستر والمجفف والبودرة

4)خطوط تعليب وتغليف الفاكهة والخضروات

5)خطوط انتاج المواسير البلاستيك والبى فى سى والبولى ايثيلين

6)خطوط انتاج التراى كالسيوم فوسفات والحبر الاسود

7)خطوط انتاج الاسفلت بانواعه

محطات معالجة الصرف الصناعى والصحى بالطرق البيولوجية والكيميائية محطات معالجة الصرف الصناعى والصحى بالطرق البيولوجية والكيميائية9)محطات معالجة وتنقية مياه الشرب

10)محطات ازالة ملوحة البحار لاستخدامها فى الشرب والرى

11)الغلايات وخطوط انتاج البخار الساخن المكثف

12)الشيللرات وابراج التبريد المفتوحة وخطوط انتاج البخار البارد المكثف

للاستعلام

مجموعة تكنولاب البهاء جروب

0117156569

0129834104

0163793775

القاهرة-شارع صلاح سالم-عمارات العبور-عمارة 17 ب فلا تر رملية/كربونية/زلطيه/حديدية

وحدات سوفتنر لازالة عسر المياه

مواصفات مياه الشرب

Drinking water

acceptable

values

50 | colour | acceptable | Taste | nil | Odour | 6.5-9.2 | ph |

1 mg/dl | pb | 5 mg/dl | as | 50 mg/dl | cn | 10 mg/dl | cd | 0-100mg/dl | hg | 8 mg/dl | f | 45 mg/dl | N02 | 1 mg/dl | Fe | 5 mg/dl | Mn | 5.1 mg/dl | Cu | 200 mg/dl | Ca | 150 mg/dl | Mg | 600 mg/dl | Cl | 400 mg/dl | S04 | 200 mg/dl | Phenol | 15 mg/dl | zn |

الحدود المسموح به

ا لملوثات الصرف الصناعى

بعد المعالجة

Acceptable

values

treated wate water

|

7-9.5 | ph | 25-37 c | Temp | 40 mg/dl | Suspended solid | 35 mg/dl | bod | 3 mg/dl | Oil & grase | 0.1 mg/dl | hg | 0.02 mg/dl | cd | 0.1 mg/dl | cn | 0.5mg/dl | phenol | 1.5 ds/m | conductivity | 200 mg/dl | na | 120 mg/dl | ca | 56 mg/dl | mg | 30 mg/dl | k | 200 mg/dl | cl | 150 mg/dl | S02 | 0.75 mg/dl | Fe | 0.2 mg/dl | Zn | 0.5 mg/dl | Cu | 0.03 mg/dl | Ni | 0.09 mg/dl | Cr | 0.53 mg/dl | لb | 0.15 mg/dl | pb |

محطات تحلية مياه البحر بطريقة التقطير الومضى على مراحل MSF+3.jpg (image)محطات التقطير الومضى لتحلية مياه البحر2![[MSF+3.jpg]](https://2img.net/h/4.bp.blogspot.com/_SynCnHGx75g/Shl2T3oVhsI/AAAAAAAAAEY/_7oem5pvQ3I/s1600/MSF%2B3.jpg) some of types of tanks we services

انواع الخزانات التى يتم تنظيفها

ASME Specification Tanks

Fuel Tanks

Storage Tanks

Custom Tanks

Plastic Tanks

Tank Cleaning Equipment

Double Wall Tanks

Septic Tanks

Water Storage Tanks

Fiberglass Reinforced Plastic Tanks

Stainless Steel Tanks

Custom / Septic

مراحل المعالجة الاولية والثانوية والمتقدمة للصرف الصناعى

صور مختلفة

من وحدات وخزانات معالجة الصرف الصناعى

التى تم تصميمها وتركيبها من قبل المجموعة

صور

من خزانات الترسيب الكيميائى والفيزيائى

لوحدات معالجة الصرف الصناعى

المصممة من قبل المحموعة

technolab el-bahaa group

technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa group technolab el-bahaa groupمياه رادياتير اخضر اللون

بريستول تو ايه

انتاج شركة بريستول تو ايه - دمياط الجديدة

مجموعة تكنولاب البهاء جروب

اسطمبات عبوات منتجات شركة بريستول تو ايه-دمياط الجديدة مياه رادياتير خضراء فوسفورية من انتاج شركة بريستول تو ايه بترخيص من مجموعة تكنولاب البهاء جروب

زيت فرامل وباكم DOT3

|

|

| | تدوير الزيوت المعدنية المستعملة واعادة استخدامها |  |

| | | كاتب الموضوع | رسالة |

|---|

Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

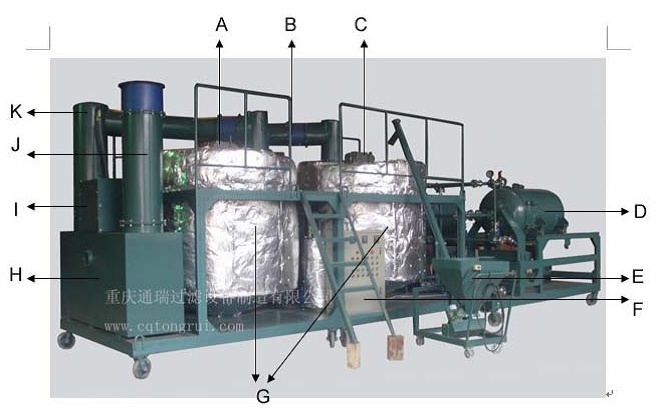

|  موضوع: تدوير الزيوت المعدنية المستعملة واعادة استخدامها موضوع: تدوير الزيوت المعدنية المستعملة واعادة استخدامها  الثلاثاء سبتمبر 04, 2012 12:36 pm الثلاثاء سبتمبر 04, 2012 12:36 pm | |

| [img]  [/img] [img]  [/img] [img]  [/img] [img]  [/img] [img]  [/img] [img]  [/img] | |

|   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

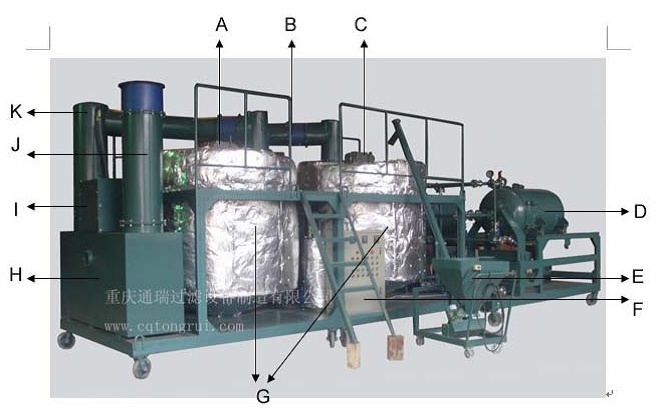

|  موضوع: ماكينات والات ومعدات تدوير الزيوت المعدنية المستعملة واعادة تدويرها موضوع: ماكينات والات ومعدات تدوير الزيوت المعدنية المستعملة واعادة تدويرها  الثلاثاء سبتمبر 04, 2012 12:47 pm الثلاثاء سبتمبر 04, 2012 12:47 pm | |

| [img]  [/img] [img]  [/img] [img]  [/img] [img]  [/img] [img]  [/img] | |

|   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

|  موضوع: مصنع تدوير الزيوت المعدنية المستعملة واعادة تدويرها موضوع: مصنع تدوير الزيوت المعدنية المستعملة واعادة تدويرها  الثلاثاء سبتمبر 04, 2012 12:51 pm الثلاثاء سبتمبر 04, 2012 12:51 pm | |

| [img]  [/img] | |

|   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

| |   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

|  موضوع: طرق تدوير الزيوت المعدنية المستعملة واعادة تدويرها ومواصفاتها القياسية موضوع: طرق تدوير الزيوت المعدنية المستعملة واعادة تدويرها ومواصفاتها القياسية  الثلاثاء سبتمبر 04, 2012 1:11 pm الثلاثاء سبتمبر 04, 2012 1:11 pm | |

| نظرية عمل وحدة تدوير الزيوت المستعملة لاعادة استعمالها

الطرق الكيماوية لإعادة تنقية الزيوت العادمة ويمكن تلخيص أهمها كما يلى :

1-طريقة الحمض –الطيني Acid Clay Process

2-طريقة الطين المنشط Acid Activated Clay Process

.

3-طريقة التقطير الفراغي Vaccum Distillation

a)مبخرات فلميه Thin Film Evaporator

b)مبخرات أنبوبية Pipe Furnace Vaporizer

4- طريقة الاستخلاص بمذيب Solvent Extraction

الطريقة الميكانيكية الكيميائية المتبعة حاليا:-

وتستخدم في هذا المشروع وحدة ترشيح متحركة صممت لهذا الغرض وتتكون من مضخة ومرشح ذو شبكة معدنية موضوعة في حوض الزيت وقبل المضخة الترسية وتتراوح مسامية هذه الشبكة من 75إلي100 ميكرون لتقوم بحجز الحبيبات الرملية الكبيرة والرايش من الدخول إلي المضخة .

كما زودت هذه الوحدة بفلتر ذو مسامية من 5 إلي 15 ميكرون موضوع بعد المضخة مباشرة حيث يتكون هذا المرشح من ألياف سيلولوزية مرتبة بحيث تقل المسامية في الحجم في اتجاه السطح الداخلي للمرشح وبالتالي فإن الحبيبات الكبيرة تحجز عند الحواف الخارجية للمرشح بينما الحبيبات الأقل حجما تحجز في عميق المرشح حتى تضيق وبالتالي تضيق المسامية كلما اتجهنا في العمق .

ولهذا المرشح قدرة عالية علي امتصاص الحبيبات وبالتالي يزيد من عمر المرشح ويجعل المرشح مناسبا لترشيح السوائل التي تحتوي علي ملوثات عالية التركيز ويلي هذا المرشح مرشح آخر ذو مسامية من 0.5إلي 5 ميكرون ومكون من ثلاث طبقات مزودة بورق سيلولوزي للترشيح الخشن وطبقة في الأوسط وبعد ذلك طبقة ورقية من ألياف الزجاج لعملية الترشيح الدقيقة وبعد ذلك ورقة داخلية من السيلولوز لزيادة عملية التثبيت .

مواصفات الزيوت المستهلكة المسموح استخدامها كوقود

الخاصية

الحد الأقصى المسموح به ملغم/لتر (جزء في المليون)

الحديد

6جزء بالمليون

الزرنيخ

5 جزء في المليون

الكادميوم

2 جزء في المليون

الرصاص

100جزء في المليون

الكروم

10 جزء في المليون

درجة الوميض

لاتقل عن 7ر37م

الهالوجينات الكلية*

4000 جزء في المليون

السيليكا الكليه

10 جزء بالمليون

*مع الافتراض ان الزيوت التي تحتوي على هالوجينات اكثر من 1000 جزء في المليون تكون مخلوطة بنفايات مهلجنة .

| |

|   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

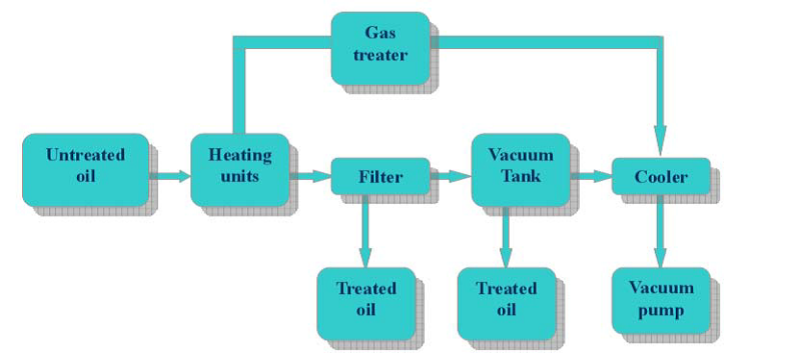

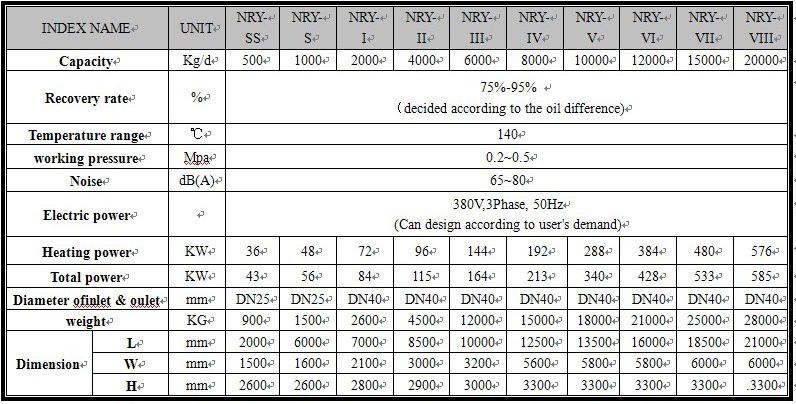

|  موضوع: معاملات مواصفات وحدة تدوير الزيوت المعدنية المستعملة واعادة تدويرها موضوع: معاملات مواصفات وحدة تدوير الزيوت المعدنية المستعملة واعادة تدويرها  الثلاثاء سبتمبر 04, 2012 1:18 pm الثلاثاء سبتمبر 04, 2012 1:18 pm | |

| [img]  [/img] | |

|   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

|  موضوع: تصميم وتصنيع وتوريد وحدة تدوير الزبوت المعدنية لبمستعملة موضوع: تصميم وتصنيع وتوريد وحدة تدوير الزبوت المعدنية لبمستعملة  الثلاثاء سبتمبر 04, 2012 1:49 pm الثلاثاء سبتمبر 04, 2012 1:49 pm | |

| [img]  [/img] [img]  [/img] | |

|   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

|  موضوع: طرق ندوير الزيوت المستعملة واعادة تدويرها موضوع: طرق ندوير الزيوت المستعملة واعادة تدويرها  الأربعاء سبتمبر 05, 2012 2:33 am الأربعاء سبتمبر 05, 2012 2:33 am | |

| [img]  [/img] | |

|   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

|  موضوع: طرق تدوير الزيوت المعدنية المستعملة واعادة تدويرها موضوع: طرق تدوير الزيوت المعدنية المستعملة واعادة تدويرها  الأربعاء سبتمبر 05, 2012 2:47 am الأربعاء سبتمبر 05, 2012 2:47 am | |

| used oil recycling / reprocessing technologies

1-Acid - Clay Process

2-Acid Activated Clay Process

.

3-Vacuum Distillation

Pipe Furnace Vaporizer4

5-Solvent Extraction Process

-----------------------------------------------------------------------------------------

Acid - Clay Process

Features:

Acid-Clay Process for used oil recycling/reprocessing is Old and popular.

Proven technology worked for many years worldwide.

Can be

set-up for very small capacity

.

» Low Capital investment. Makes it most cost effective for small and tiny scale plants.

» Non sophisticated, Very simple process. Simple to operate, No advanced instruments,

No skilled operators required.

Drawbacks:

» Causes Environmental pollution due to generation of acid sludge and acid gas emission.

Disposal of acid sludge is a problem.

» Causes corrosion of equipments reducing its life.

» Gives Lower yield. Due to loss of oil in sludge as well as clay since higher dosage of clay is required.

» As most of the government has adopted stringent pollution control regulations, this process is on its way out.

--------------------------------------------------------------------------------------

Acid Activated Clay Process :-

Features

» No acid is required.

» It is simple process

» Suitable for small capacity plant.

Drawbacks:

» Very high clay consumption, low yield, inconsistent quality.

» Disposal of large quantity of spent clay is a environmental problem.

» Suitable only for very small capacity plants.

» Process is dependent on a particular type of clay which may not be available from all the sources.

-------------------------------------------------------------------------------------

Vacuum Distillation

Thin/Wiped Film Evaporator

Features:

» Suitable for high capacity plants.

» Thin film evaporator is capable of Operating at high vacuum and normally used for high value and heat sensitive products.

» Does not cause pollution.

» Sophisticated Equipments & Process

» Produces good quality Base Oils.

Drawbacks:

» Operates at high temperature & very high Vacuum. Require special /expensive thermic fluids & heating system.

High cost of heating fluid and High operational costs.

» Requires high capital investment.

» Plant has to be of a higher capacity to make it economically viable.

» Require highly skilled & Operational maintenance Staff. As it has very sophisticated equipments.

» Higher Fuel Cost.

» Due to multiple stage of distillation involving heating & cooling.

----------------------------------------------------------------------------------------

Pipe Furnace Vaporizer

Features:

» Simple pipe furnace, convection heating at low heat flux by re-circulating flue gases.

» No moving part on process side.

» No prior removal of gas oil is required.

» Simple instrumentation.

---------------------------------------------------------------------------------------

Solvent Extraction Process

Features:

» In this process propane is used as solvent to remove bitumen, additives, metals and tar etc.

» Solvent is recyclable.

» Does not cause pollution.

» Produce Good quality Base Oils.

Drawbacks:

» Has to operate at higher pressure ( 10 atm. ) at ambient temperature ( 27oC ) require high pressure sealing systems.

(making system expensive and complicated)

» Involves operational solvent losses and highly skilled operating and maintenance personnel and system is required.

» Economical only for high capacity plants.

» Propane being very hazardous, Fire & explosion hazard is associated with this process. | |

|   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

|  موضوع: خطوات طرق تدوير الزيوت المستعملة واعدة تدويرها موضوع: خطوات طرق تدوير الزيوت المستعملة واعدة تدويرها  الأربعاء سبتمبر 05, 2012 3:02 am الأربعاء سبتمبر 05, 2012 3:02 am | |

|

Oil Recycling Process

Pretreatment

Used oil undergoes a pretreatment step in the overall recycling process.

The recycled oil is dewatered to get rid of its water content.

The main tool used to dewater oil is gravity.

The process involves allowing the natural separation of the oil from the water over time

When the two have separated into an upper layer of oil and a bottom layer of water,

the water is then drained from the oil and undergoes a treatment process to make it safe for disposal into the environment.

Heat is also used in the dewatering process to speed it up by causing the water to evaporate. Once the water is separated out of the oil, it is then ready for the next step,

---------------------------------------------------------------------------------------

Filtering

Debris and additives are filtered out of the recycled oil.

Some of the additives extracted by filtering are also recycled for reuse.

The used oil is placed in a reaction tank, where it is mixed with sulfuric acid and then heated.

--------------------------------------------------------------------------------------

Demineralization

A surfactant is added to the mixture, which is then left to separate into oil and a water-based, soap-like phase.

This water-based part collects debris and contaminants, such as oil additives and metals, and then it is drained off at the bottom of the tank.

The water is then evaporated off, and the waste is disposed of as solid matter.

The oil is filtered again to remove finer particles of debris.

The oil is then ready to be used as fuel, and can undergo further refining to produce different grades of fuel oils, from heavy fuels to lighter fuels for specialized burners.

------------------------------------------------------------------------------------------

Propane Deasphalting

Propane deasphalting (PDA) is the refining process that removes asphalt from the recycled oil.

The used oil is fed into the deasphalting apparatus, where liquid propane is added from the bottom of the tank.

As the propane rises through the oil, and the oil settles, it dissolves the lube oil elements, separating them out of the oil, and allowing them to collect at the bottom of the tank.

The propane is then recycled by retrieving it from both the oil and the waste through vaporization.

The vaporized propane is then collected, condensed and stored for future use in the PDA process.

--------------------------------------------------------------------------------------

Distillation

Recycled oil can also undergo distillation to remove water, gases, petrol and solvents.

The first type of distillation is atmospheric distillation, a process that separates these components from the oil based on their respective boiling points.

As the recycled oil is heated in the distillation process up to 300 degrees Celsius, each component boils off and is collected for reuse.

Another type of distillation is vacuum distillation, which further refines the oil to control its flash point, viscosity and carbon residue.

The recycled oil undergoes heating at temperatures higher than 300 degrees Celsius, as the vacuum system works to reduce pressure build-up that, in turn, prevents destruction of the oil components.

The oil is heated and distilled off into trays, as different grades of oil.

The lightest is gas oil, which is distilled off at the highest level of the system.

This is followed by light oil, medium oil and heavy oil.

This process separates out the remaining components, called vacuum tower bottoms (VTB), the heaviest components in the oil, that were unaffected by the distillation process. | |

|   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

|  موضوع: خطوات طرق تدوير الزيوت المعدنية المستعملة واعادة استخدامها2 موضوع: خطوات طرق تدوير الزيوت المعدنية المستعملة واعادة استخدامها2  الأربعاء سبتمبر 05, 2012 3:08 am الأربعاء سبتمبر 05, 2012 3:08 am | |

| [img]  [/img] | |

|   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

|  موضوع: خطوات طرق تدوير الزيوت المعدنية المستعملة واعادة تدويرها3 موضوع: خطوات طرق تدوير الزيوت المعدنية المستعملة واعادة تدويرها3  الأربعاء سبتمبر 05, 2012 3:10 am الأربعاء سبتمبر 05, 2012 3:10 am | |

| [img]  [/img] | |

|   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

|  موضوع: استخدامات الزيوت المعدنية المستعملة بعد تدويرها بناءا على طريقة التدوير المستخدمة موضوع: استخدامات الزيوت المعدنية المستعملة بعد تدويرها بناءا على طريقة التدوير المستخدمة  الأربعاء سبتمبر 05, 2012 3:35 am الأربعاء سبتمبر 05, 2012 3:35 am | |

|

Uses for recycled oil

What happens to your recycled used oil

Pre-treatment or Dewatering

Filtering & Demineralisation

Propane De-asphalting

Distillation

---------------------------------------------------------------------------------------

What happens to your recycled used oil

Used oil, or 'sump oil' as it is sometimes called, should not be thrown away.

Although it gets dirty, used oil can be cleaned of contaminants so it can be recycled again and again.

There are many uses for recycled used oil.

These include:

Industrial burner oil, where the used oil is dewatered, filtered and demineralised for use in industrial burners;

Mould oil to help release products from their moulds (e.g. pressed metal products, concrete);

Hydraulic oil;

Bitumen based products;

An additive in manufactured products; or

Re-refined base oil for use as a lubricant, hydraulic or transformer oil.

Once you have taken your used oil to your local collection facility, used oil collectors take the used oil and undertake some pre-treatment and recycling of the used oil or sell it to a specialised used oil recycler.

----------------------------------------------------------------------------------------

Pre-treatment or Dewatering

Pre-treatment of used oil involves removing any water within the oil, known as dewatering.

One way of doing this is by placing it in large settling tanks, which separates the oil and water.

Further recycling steps include:

Filtering & demineralisation of the oil, to remove any solids, inorganic material and certain additives present in the oil, producing a cleaner burner fuel or feed oil for further refining;

Propane de-asphalting to remove the heavier bituminous fractions, producing re-refined

base oil;

and

Distillation to produce re-refined base oil suitable for use as a lubricant, hydraulic or transformer oil.

This process is very similar to the process undergone by virgin oil.

Water is found in used oil as free water or bound water, for example in emulsions.

The term dewatering is usually taken to mean the removal of free water.

Where water has been emulsified with oil, the emulsion has to be "broken" with a demulsifier before the water can be separated from the oil.

Dewatering is a simple process relying on the separation of aqueous and oil phases over time under the influence of gravity.

The used oil is allowed to stand in a tank (raw waste oil) and free water drops to the bottom where it can be drained, treated (waste water treatment) and discharged appropriately to sewer or stormwater depending on quality and local regulations.

Heating and stirring the used oil in a tank (A) and driving off the water through evaporation can speed up the dewatering process.

The "dried" or dehydrated oil is then suitable for further processing or for use as a burner fuel.

-----------------------------------------------------------------------------------

Filtering & Demineralisation

The purpose of filtering and demineralisation is to remove inorganic materials and certain additives from used oil to produce a cleaner burner fuel or feed for re-refining.

Used oil feedstock is transferred to a reaction tank (A) and mixed with a small quantity of sulphuric acid and heated to about 60oC.

A chemical surface-active reagent, called a surfactant, is added to the reactor (A) and after stirring the mixture is allowed to stand.

This allows the mixture to separate into two "phases" - i.e. oil and water-based or aqueous.

The reagent causes the contaminants to accumulate in the aqueous phase, which settles to the bottom of the tank (A) and is drained off as slurry.

This phase contains acid, used oil contaminants, including metals and some of the oil additives. The water is dried off, leaving a solid waste that must be disposed of.

The demineralised oil is filtered (B) to remove suspended fine particles (to solid waste) and run off to storage (C) as a clean burner fuel.

It can be further diluted or "cut" with a lighter petroleum product (called cutter stock) to produce a range of intermediate to light fuel oils depending on the fuel viscosity requirements of the burner.

--------------------------------------------------------------------------------------

Propane De-asphalting

The Propane De-asphalting (PDA) process is an important pre-treatment step in the re-refining process producing de-asphalted lube-oil, which becomes a feedstock for the next step in a re-refining facility.

The other output (which is also an input) is propane, which is recovered from both streams and re-used within the process.

The PDA process relies on the greater solubility of the paraffinic and naphthenic (ie essentially the base oil) components versus the contaminated waste material in a stream of propane.

The separation of the lubricating oil fraction from used oil is a continuous process and is conducted at ambient temperature when processing used oil.

The used oil is pumped into the middle of the extraction column (A).

Liquid propane is charged to the bottom of the column (A).

The oil being heavier than propane, flows down the column (A); the propane rises in a counter-flow thus mixing the input streams within the column (A).

The rising propane dissolves the more soluble lube oil components, which are carried out the top of the column (A) with the propane, and the propane insoluble material is removed from the bottom of the column (A).

Propane is vaporised from both streams [ie., the de-asphalted lube-oil stream (B) and the waste stream (C)] in "stripper" units (B) and (C), then condensed and returned to the propane storage tank.

The de-asphalted lube-oil component is feed for the next processing stage.

The residuum (waste) component is mixed with bottoms from the vacuum distillation tower to produce an asphaltic material.

----------------------------------------------------------------------------------------

Distillation

Distillation (or Fractionation) is the physical separation of components of lubricating oil by boiling range.

Depending on the type of distillation, the boiling ranges can produce gases and gasolines at the lower boiling points with heavy lubricating oils being distilled at higher boiling points.

Distillation is the core process for a facility capable of producing re-refined base-oils to virgin base-oil quality.

There are 2 types of distillation, atmospheric and vacuum.

=====================================================

Atmospheric Distillation

Atmospheric distillation is generally (but not always) considered a pre-treatment step for vacuum distillation and does not require de-watered feedstock.

Atmospheric distillation is carried out at normal atmospheric pressure and with temperatures up to 300°C.

Prior to the atmospheric distillation process, the feedstock can have undergone PDA treatment, but this is not an absolute pre-requisite.

Atmospheric distillation is a relatively simple process separating lower boiling point liquids at ambient pressure.

Used oil is heated (A) and charged to a distillation tower (B).

Lower boiling point hydrocarbons present in the used oil (eg gases, petrol and solvents) and water are collected at the top of the tower (B).

Some of these hydrocarbons can be condensed and collected for use as a fuel in the refining process.

This process is only suitable for temperatures up to 300oC, as temperatures above this can lead to "thermal cracking" of the larger molecule (higher boiling point) hydrocarbons, ie. the actual lube oil molecules we are aiming to recover.

After atmospheric distillation the oil usually undergoes vacuum distillation.

Note that used oil can be sent directly from a "drying" process to a vacuum distillation unit without necessarily undergoing atmospheric distillation.

However, it is generally accepted that water and lower boiling point hydrocarbon components be removed prior to vacuum distillation.

======================================================

Vacuum Distillation

Vacuum distillation is considered the key process in used oil re-refining.

If atmospheric distillation is utilised, the oil from the atmospheric distillation column is the feedstock for the vacuum distillation column.

In vacuum distillation the feedstock can be separated into products of similar boiling range to better control the physical properties of the lube base stock "distillate cuts" that will be produced from the vacuum tower products.

The major properties that are controlled by vacuum distillation are viscosity, flash point and carbon residue.

The viscosity of the lube-oil base-stock is determined by the viscosity of the distillate in terms of its relative viscosity separation, eg. light, medium and heavy oil.

The used oil feedstock (usually from the atmospheric distillation unit) is heated in a furnace (A) and flows as a mixture of liquid and vapour to the heated vacuum distillation column (B) where the vapour portion begins to rise and the liquid falls.

Steam can be added to assist vaporisation.

A vacuum is maintained in the column (2-10 mm Hg) by a vacuum system connected to the top of the tower (B).

By reducing the pressure, materials normally boiling at up to about 540oC at atmospheric pressure, can be vaporised without thermal cracking.

As the hot vapours rise through the column (B), they cool and some condense to a liquid and flow back down the column.

Similarly, some of the downward flowing liquids are re-vaporised by contacting the rising hot vapours. Special devices in the column allow this upward flow of vapours and downwards flow of liquids to occur continuously.

At various points in the column (B), special trays, called draw trays, are installed which permit the removal of the liquid from the column.

If three cuts or "fractions" of oil are required to produce light, medium and heavy base stocks, then three draw trays are positioned appropriately.

This can be reduced to two draw trays if, for example, only 2 cuts or fractions are required.

Some of the material does not boil even under this vacuum.

This remains in the vacuum tower and is run out as the vacuum tower bottoms (VTBs).

This material contains the heaviest molecules, including some lube oil additives and carryover contaminants not removed in the PDA process. (Note: not all re-refining plants have PDA units).

| |

|   | | Admin

Admin

عدد المساهمات : 3762

تاريخ التسجيل : 15/09/2009

العمر : 57

الموقع : مصر

|  موضوع: رد: تدوير الزيوت المعدنية المستعملة واعادة استخدامها موضوع: رد: تدوير الزيوت المعدنية المستعملة واعادة استخدامها  الأربعاء سبتمبر 05, 2012 3:45 am الأربعاء سبتمبر 05, 2012 3:45 am | |

| [img]  [/img] [img]  [/img] [img]  [/img] [img]  [/img] [img]  [/img] | |

|   | | | | تدوير الزيوت المعدنية المستعملة واعادة استخدامها |  |

|

مواضيع مماثلة |  |

|

| | صلاحيات هذا المنتدى: | لاتستطيع الرد على المواضيع في هذا المنتدى

| |

| |

| |

|

![[MSF+3.jpg]](https://2img.net/h/4.bp.blogspot.com/_SynCnHGx75g/Shl2T3oVhsI/AAAAAAAAAEY/_7oem5pvQ3I/s1600/MSF%2B3.jpg)